Fiber Lasers - LOGILASE website

Main menu:

- HOME

- PRODUCTS

-

SPECIFICATIONS

- CO2 Lasers

- Fiber Laser Cutting

- Fiber Laser Marking

- LASER EDUCATION

- VIDEO SHOWCASE

- SERVICES & WARRANTY

- CONTACT US

Fiber Lasers:

One of the most common types of fiber lasers is the Erbium-

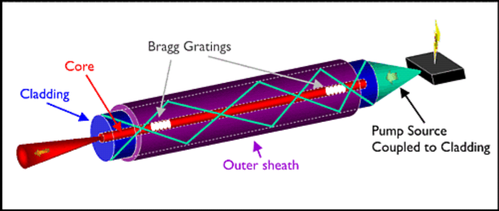

Within the doped fiber, we have our 'laser medium', which is the erbium atoms. The photons that are emitted are confined inside the fiber core. To create our laser cavity, we add Bragg Gratings. A Bragg Grating is a section of glass that has stripes in it where the refractive index has been changed. Each time the light goes across a boundary between one refractive index and another, a bit is reflected back. If you have enough stripes, the grating acts like a very efficient mirror.

Diode lasers produce messy beams, so they aren't very useful for a lot of the things we want to do. They can also be stacked, so that you get the power from lots of diode lasers being used to pump a single fiber laser with large amounts of power. The problem is that the fiber core is too small for us to focus the diode laser into it. To get around this, we focus the pump laser into the much-

Fiber Lasers Advantages:

The first reason a fiber laser is useful is because it is stable. When we want to deliver a laser beam, we usually need an optical fibre to move it around safely. The alternative is to bounce it between mirrors, but these need to be very finely aligned. Coupling a laser beam into the tiny core of a fibre is very hard, and also needs to be finely adjusted. So normal lasers are very sensitive to being knocked or banged, and once the optics go out of alignment it takes a specialist to sort them out.

In contrast, the fiber laser generates the beam inside the fibre, so the delivery of the beam doesn't require any complicated or sensitive optics. This makes it very stable and easy to use.

The second reason a fiber laser is useful is because the beam quality is so high. The beam is generated and confined inside the small core of the fibre. In practise, this means that the beam is very straight, and that it can be focused on a very small dot. The smaller the dot, the more effective the laser will be for cutting, for example, but in many uses for lasers this quality is required.

The third reason is because they can be made to go up to very high powers. Lasers start to get to the point where they can harm your skin at around 1 Watt of power. This isn't very much power compared to a kettle or a toaster, but when it is all focused on a single point it seems like a lot! It's the difference between being gently warmed by the sun, or having a big lense focus the sun onto you, creating a powerful beam.

Fiber lasers are continually getting more powerful, and have been made with over 4,000 Watts of power (4kW). That is more than enough to cut through 1 inch of steel!

The fourth reason is that they are very efficient and easy to cool. Other lasers may only be able to convert a small percentage of the power put into them, but a fiber laser converts around 70-